What is the TNG Geothermal Wellhead Equipment Repair Tool (GWERT™)?

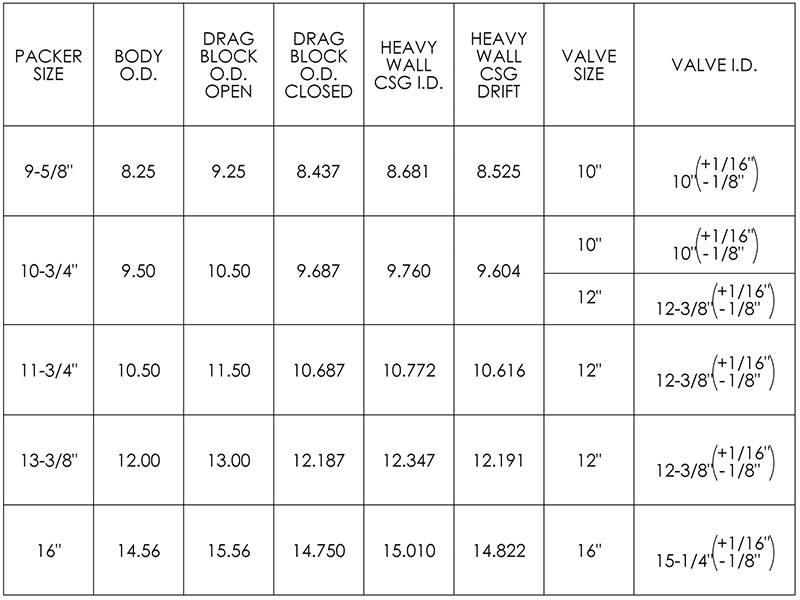

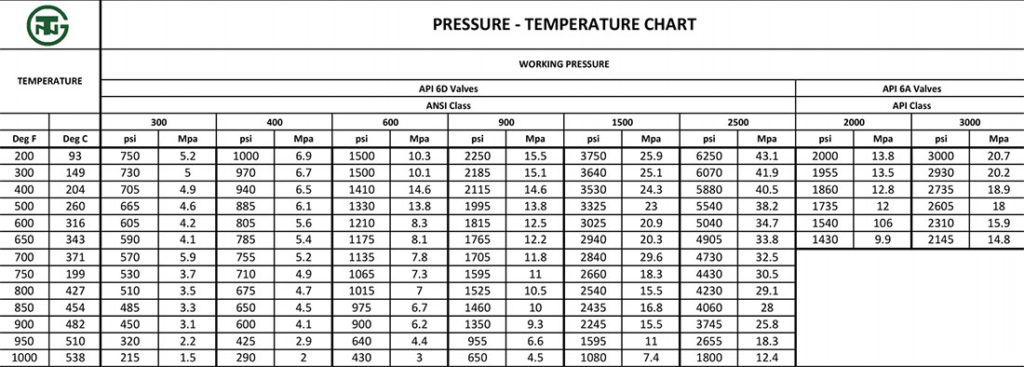

The tool is a downhole packer designed to be set in high pressure, high temperature (HPHT) geothermal wells. The packer is rated to 1000 psi at 450°F (but can be operational up to 1500 psi and 650°F) and available for casing sizes 7” through 16”. The system allows the setting of the GWERT™ to a depth of 50 feet into the wellbore, and once it is set and the pressure is relieved, the packer is released and left in hole. This enables TNG to safely change out valves and wellheads, repair surface casing and provide specialized wellhead maintenance on the well.