The geothermal industry is known as renewable energy and a clean energy source but inherent properties make this energy anything but clean. Minerals and deposits in geothermal reservoirs create a scale that is persistent in its corrosive nature. Additionally, heat extremes and pressure variations present challenges to the integrity of the wellhead components and the downhole casing. Such challenges must be mitigated to achieve maximum output from these aging or even newly commissioned wells.

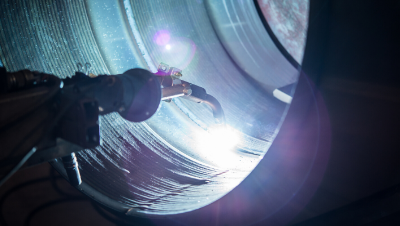

Certified welding procedures, corrosion, and wear-resistant welding materials, and of course qualified welders are the front line of defense within the industry. We will present a case study showing the need to adopt and follow certified welding procedures as well as evidence of the effects that can happen when these procedures are neglected. Oftentimes one will forego using a certified welder or procedure to accomplish a repair for the sake of budgetary concerns. We will also show the economic impact of using these certified procedures.

When considering options for wellhead installation or equipment repair, one must ask some basic but critical questions. Who is going to perform the welding? Is the welding certified, that is, does a procedure exist? Is the procedure validated independently? And finally, is the welder performing the work qualified for the procedure? If the answer to all these questions is yes, proceed with confidence.

Read our complete technical paper from the 2019 GRC Annual Meeting and Expo: Welding; Properties, Characteristics, and Applications in the Geothermal Industry

Visit the GRC’s website to learn more about the 2020 GRC Annual Meeting.